- Parts

- Culture

- Garage

- Technology

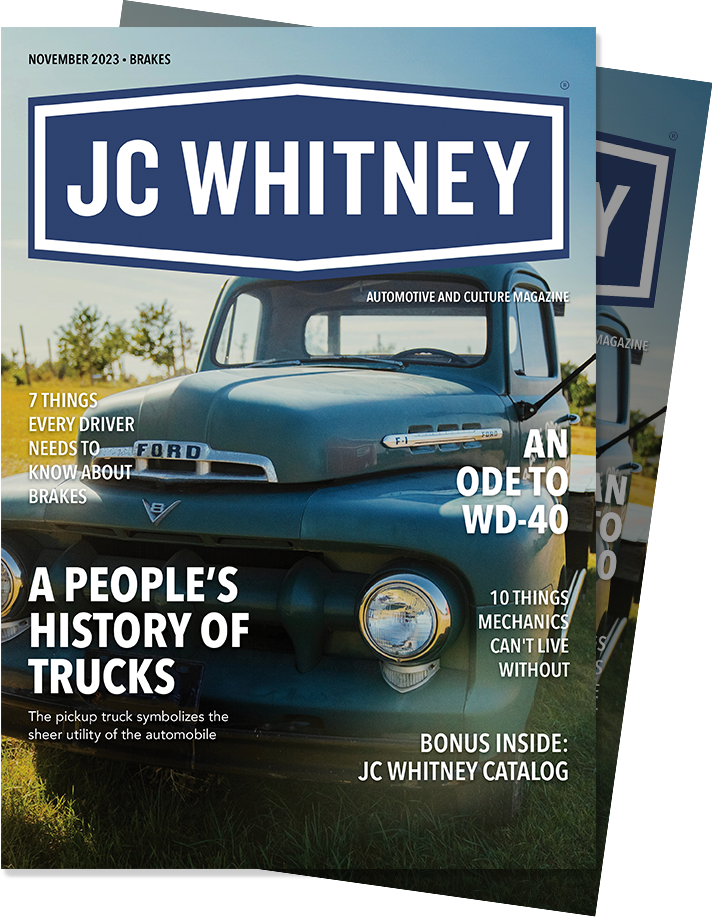

Get the Magazine

We've launched the inaugural edition of our new JC Whitney magazine! Sign up today to join the wait list.

Carlisle Events

April 17, 2024

$13

La Jolla Concours D’Elegance

April 19, 2024

Start $30+, Kids Free

The Lonestar Rod & Custom Roundup

April 19, 2024

$20