At Rancho Transaxles in Fullerton, Ca, the meticulous craftsmanship behind high-performance transaxle builds using quality EMPI parts is on full display. Lino, the expert responsible for these builds, carefully guides each step of the process, showcasing an attention to detail and precision that sets these transaxles apart.

Starting with the Gears

Building a transaxle is never rushed – every step is deliberate and serves a specific purpose. Lino begins by working with the original pressed-on gears, grinding the sides and welding them back on to ensure they can withstand high horsepower without slipping. This process involves pressing the gear off, carefully prepping it, and welding it back on, ensuring that each transmission is built to handle significant stress.

Polishing for Perfection

A key element of the build process is the polishing of components, not just for appearance but for optimal performance. Every part – from shift rails to synchros – is polished and cleaned to ensure smooth operation and longevity. Lino meticulously deburrs and sands the gears, ensuring they don’t just function properly but also provide a seamless shifting experience.

Polishing isn’t a special step reserved for certain builds; it’s part of every transmission build at Rancho. Lino emphasizes that each part is polished to ensure smoothness, resulting in no drag or sticking during gear shifts – just precision.

Building with Precision

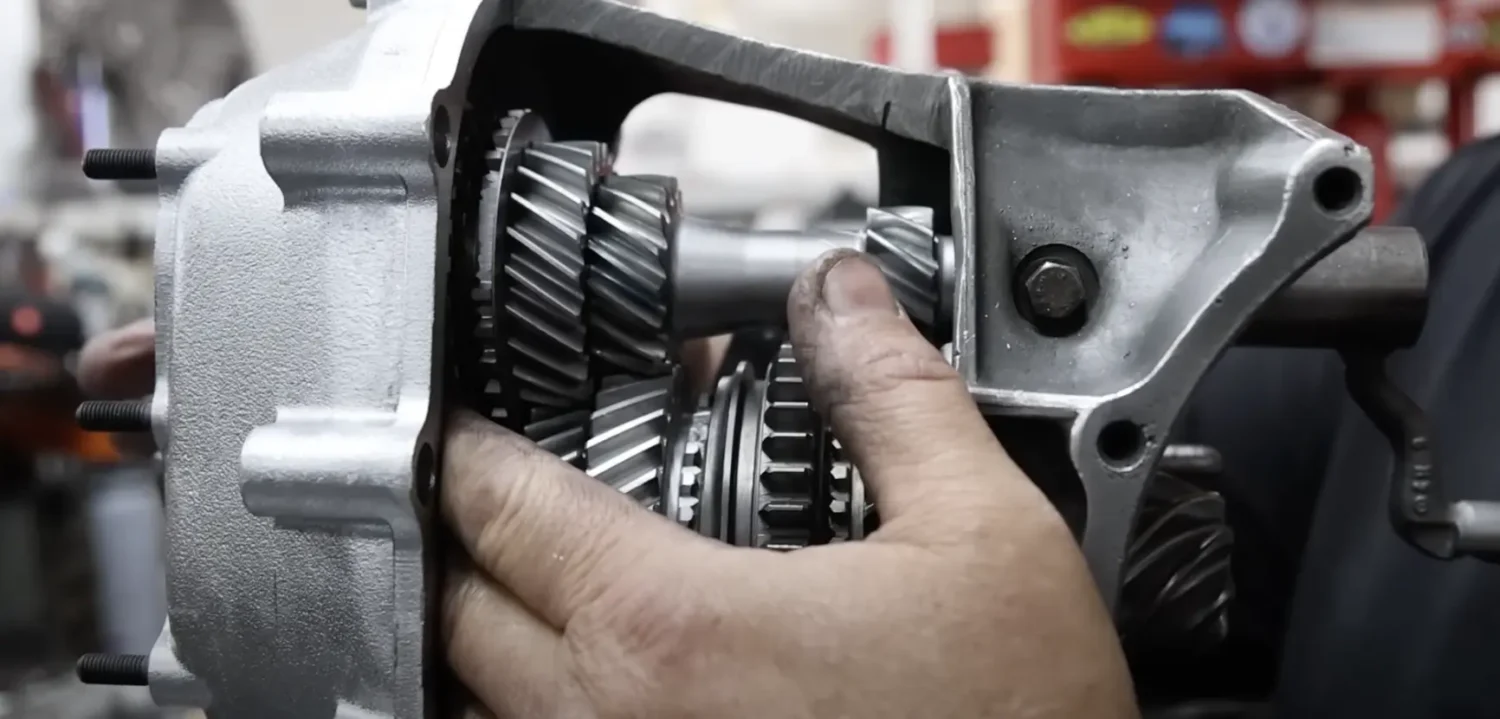

Assembling the gears requires an expert’s touch, and Lino demonstrates his ability to gauge tolerances by feel, a skill developed through years of experience. Each gear and synchro is inspected, with WD-40 applied for smoothness, ensuring there are no binds in the mechanism. This level of precision doesn’t come quickly; it’s a craft that’s been perfected over time.

One crucial part of the assembly involves lining up the third and fourth gears and setting the tolerance precisely. Even a minor misalignment can cause issues down the line, such as too much movement in third gear, which could lead to spring pops or broken parts. Lino’s attention to detail ensures every clip and bearing is perfectly positioned, providing the durability and reliability needed for high-performance use.

Gearing Up for Power

As the build progresses, special attention is given to ensuring that the transaxle can handle significant power. Lino installs a hardened key on the main shaft to prevent shearing and polishes the edges of the slider dogs, allowing for smooth movement. Every part of the build is carefully inspected, adjusted, and tested to ensure it can withstand the demands of high-performance driving.

Even seemingly small details, such as the direction of a clip’s bevel, are critical to the transaxle’s performance. If not set correctly, gears could come apart under pressure. With Lino’s expertise, every element is checked and double-checked, ensuring the transaxle is built to perform under the toughest conditions.

Bringing It All Together

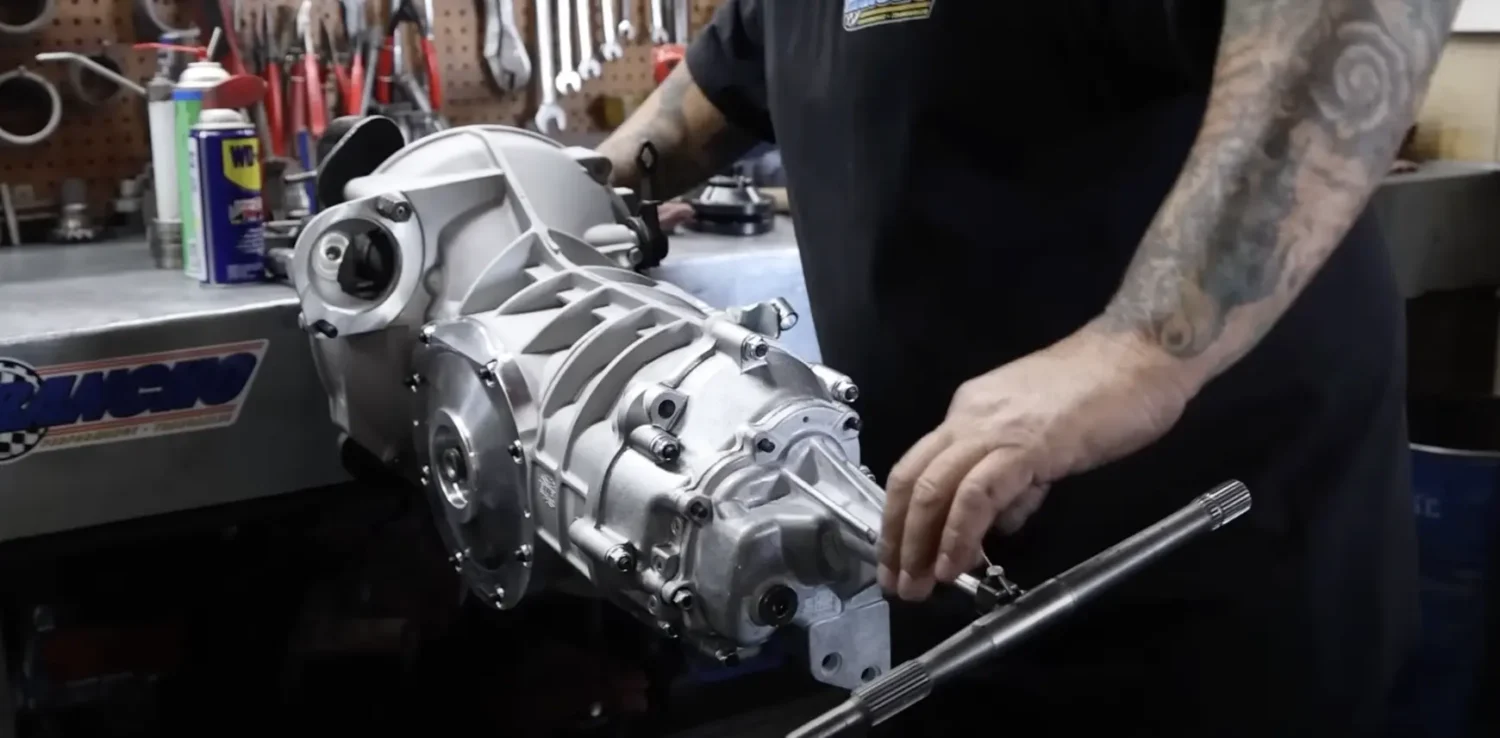

In the final stages of the build, Lino assembles the remaining components – installing a heavy-duty hockey stick, greasing the detent balls, and setting up the reverse gear. Each gear is tested thoroughly, ensuring smooth and quiet shifting. This process goes beyond simply building a functional transaxle; it’s about creating a product that delivers flawless performance under stress and stands the test of time.

As the build nears completion, the transaxle is tested one last time. The smoothness of the shifts and the quiet engagement are evidence of the precision and care invested in the process. Every detail has been meticulously crafted to ensure the transaxle is ready for high-performance action.

Final Thoughts

The process of building a high-performance transaxle at Rancho Transaxles is a masterclass in precision and craftsmanship. From welding and polishing to testing and assembling, every step is carried out with care to ensure the transaxle can handle the rigors of high-stress driving.

For those seeking a transaxle built to last, visit EMPI for all your product needs.