What you need to know about regenerative braking.

The act of stopping your car is an intensive energy transfer process. If we dust off our old science textbooks and turn to the page about thermodynamics—yep, right there on the page where you scribbled the initials of your crush—you’ll remember that energy isn’t created or destroyed. So that means the energy you used to bring your car up to speed has got to go somewhere when we slow down. In modern cars that energy is converted to heat which is created by the friction between our brake pads in the calipers and the disc rotors. As the discs are squeezed by the calipers, our car slows to a halt and heat is created. For years that energy has simply been allowed to dissipate without a second thought. But today, battery-powered hybrid and electric cars are changing that with regenerative braking, which captures the energy created by braking and uses it to power the car. This incandescent-lightbulb level innovation represents a breakthrough in automotive efficiency that will change cars forever. Join us as we explore the creation of this tech and take a look at where it’s headed in the future.

History

Regenerative braking systems were invented and initially applied in the late 19th and early 20th centuries. The concept was first applied to elevator systems and trams. In 1887, Sprague Electric Railway & Motor Company introduced regenerative braking technology in elevators. Later on, it was applied to railway systems to improve energy efficiency.

Regenerative braking systems in trains operate by converting the kinetic energy, usually lost during braking, back into electrical energy which can be reused. When a train moves, it has a significant amount of kinetic energy, and when the brakes are applied, this kinetic energy is normally dissipated as heat. However, with regenerative braking, the process is optimized for energy recovery.

In the case of electric trains, when the brakes are applied, the electric motors that drive the train’s wheels essentially turn into generators. As the wheels turn the generator while the train is slowing down, electrical energy is produced. This generated electrical energy is then either returned to the power lines and used elsewhere, or stored onboard for later use, such as for accelerating the train again or powering other systems within the train.

This system not only improves energy efficiency but also reduces wear and tear on the train’s mechanical braking systems, lowering maintenance costs. Furthermore, by converting braking energy into reusable electrical energy, regenerative braking contributes to the overall sustainability and efficiency of train operations, reducing the overall energy consumption and carbon footprint of the railway system.

For automobiles specifically, the first instances of regenerative braking were seen in electric vehicles in the early 20th century. However, it wasn’t until the advent of more sophisticated electrical and battery technologies in the late 20th century that regenerative braking became a more common feature in passenger vehicles, particularly hybrid and electric cars.

The technology has significantly evolved since its initial application, becoming a fundamental feature in modern electric and hybrid vehicles, contributing substantially to energy recovery and overall vehicle efficiency.

How it Works

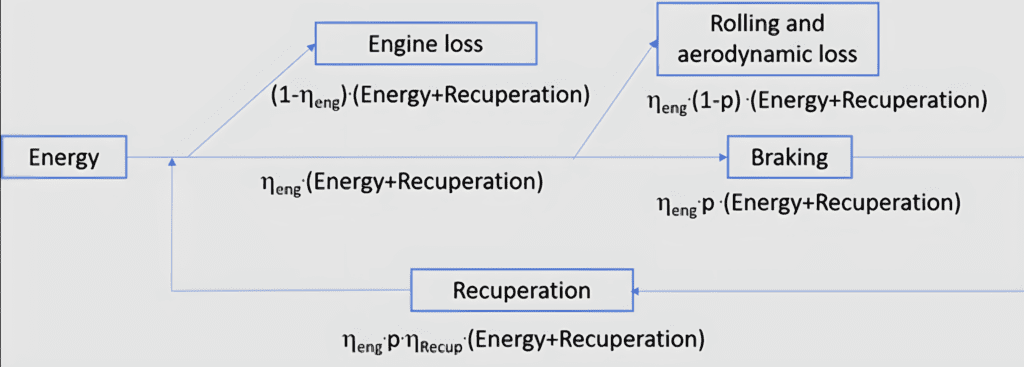

Regenerative braking in hybrid and electric vehicles (EVs) works by recapturing the kinetic energy typically lost during braking and converting it into electrical energy that can be used to recharge the vehicle’s battery. This process is integral to the enhanced energy efficiency observed in these types of vehicles.

Here’s an overview of how the process works: In a conventional braking system, applying the brakes leads to the generation of heat due to friction, and this heat is dissipated into the environment, wasting the kinetic energy of the moving vehicle. However, regenerative braking systems are designed to capitalize on this otherwise wasted energy.

When the driver applies the brakes in a hybrid or EV, the electric motor undergoes a role reversal—it switches from consuming electricity to generating motion, to generating electricity from the motion (kinetic energy) of the wheels as the vehicle slows down. This happens because the electric motor is connected to the wheels, and when the vehicle is slowing down, the wheels drive the motor, turning it into a generator.

The electricity generated by the motor-generator is directed to the battery, where it is stored for later use. This stored energy can then be used to power the vehicle’s electric motor, contributing to the propulsion of the vehicle.

Regenerative braking is particularly beneficial during city driving, where there are numerous stop-and-go situations. It contributes significantly to the efficiency of hybrid and electric vehicles, allowing them to achieve higher fuel economy and longer ranges compared to conventional internal combustion engine vehicles. This system also tends to reduce the wear and tear on the mechanical braking system, potentially lowering maintenance costs.

Nuts & Bolts

Yes, regenerative braking systems do require some different maintenance practices and components compared to conventional braking systems, but they also share some common aspects.

Regenerative braking systems involve electrical and electronic components such as the electric motor-generator and batteries, which conventional braking systems do not have. These components require specific maintenance practices to ensure they operate effectively. For instance, ensuring that the electrical connections are secure and that the battery is in good condition is essential for the proper functioning of a regenerative braking system.

However, because regenerative braking reduces the reliance on the traditional friction braking system by using the electric motor to slow down the vehicle, the mechanical brakes tend to experience less wear and tear. This could mean that components like brake pads and rotors may not need to be replaced as frequently as they would in vehicles without regenerative braking systems.

On the flip side, because mechanical brakes are used less frequently, they might be more susceptible to corrosion or other issues related to lack of use. Regular inspection is necessary to ensure that the conventional brakes are operational when needed, especially because they act as a backup and supplementary system to the regenerative brakes.

Furthermore, technicians working on regenerative braking systems need to be knowledgeable about both mechanical and electrical systems and should follow safety protocols to avoid risks associated with high-voltage electrical components.

In conclusion, while regenerative braking systems have some unique maintenance requirements due to their electrical components, they also lead to reduced wear on the conventional braking system, possibly leading to less frequent replacements of parts like brake pads and rotors. It’s essential to have the vehicle serviced by technicians familiar with regenerative braking systems and their specific maintenance needs.

Tech & Innovation

The future of regenerative braking systems in cars appears promising and intrinsically linked with the broader adoption of electric vehicles (EVs) and hybrid technologies. As the global automotive industry gravitates towards sustainability, with increasing emphasis on reducing carbon footprints and enhancing energy efficiency, the proliferation of EVs seems inevitable. In turn, as more EVs permeate the market, regenerative braking systems, a cornerstone technology for these vehicles, are likely to become more prevalent.

Innovation in regenerative braking is expected to be multifaceted. We might see advancements in the efficiency of energy recovery, whereby a larger proportion of the kinetic energy lost during braking is recaptured and reused. This could involve improvements in motor-generator technologies, battery storage capabilities, and the overarching control systems governing these processes.

Another avenue of innovation could be the integration of regenerative braking systems with other vehicular technologies, such as adaptive cruise control and autonomous driving systems. Such integration could enable more nuanced and adaptable regenerative braking strategies, optimized in real-time based on driving conditions, traffic patterns, and topographical variations.

Enhancements in the smoothness and responsiveness of regenerative braking systems could also be on the horizon. Future systems might offer an improved driving experience, with seamless transitions between regenerative and friction braking, catering to a broader spectrum of driving styles and preferences.

Furthermore, we might witness the expansion of regenerative braking concepts beyond hybrids and EVs, exploring their potential applicability in other vehicle categories, potentially even in conjunction with internal combustion engines, further broadening their impact on the automotive landscape.

Ultimately, the trajectory of regenerative braking systems is poised to be one of growth, innovation, and increasing significance in the automotive industry’s sustainable future. The technology is likely to evolve in parallel with broader trends, such as electrification and automation, playing a crucial role in shaping the next generation of vehicles and driving experiences.